The Welding Add-in offers simulation and off-line programming features. Instructions are added to the output program specific to your robot controller. An increasing number of post processor are supporting the Welding Add-in instructions, including:

1.ABB RAPID IRC5

2.ABB RAPID S4C

3.Fanuc R30i

4.Kawasaki

5.KUKA KRC2 DAT

6.Motoman

Please contact us to add support to a specific controller.

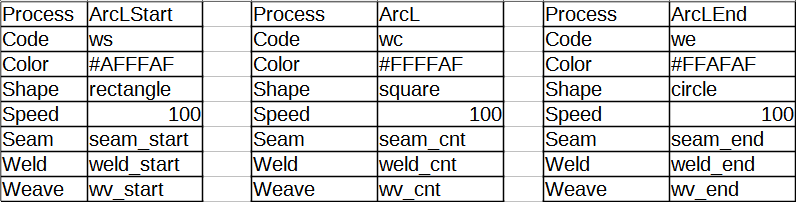

The templates abb_ws.csv, abb_wc.csv and abb_we.csv are used as ABB welding templates for weld start (ArcLStart), weld continue (ArcL) and weld end (ArcLEnd) commands respectively. The parameters 'Seem', 'Weld' and 'Weave' in these templates must be equal to the names of the corresponding welding variables on the real controller.

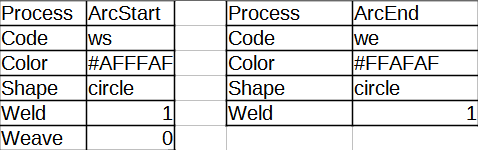

The fanuc_ws.csv and fanuc_we.csv templates are used as Fanuc welding templates for the ArcStart and ArcEnd commands respectively. ArcStart can be used again to change the welding mode directly in the process. The 'Weld' and 'Weave' parameters in these templates must be equal to the values of the corresponding welding variables on the actual controller.

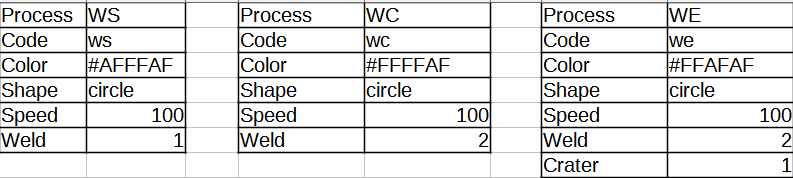

The templates kawasaki_ws.csv, kawasaki_wc.csv and kawasaki_we.csv are used as Kawasaki welding templates for the weld start (WS), weld continue (WC) and weld end (WE) commands respectively. The 'Weld' and 'Crater' parameters in these templates must be equal to the corresponding weld variables on the actual controller (e.g. W1SET and W2SET numbers).

The kuka_ws.csv and kuka_we.csv templates are used as KUKA welding templates for the ArcStart and ArcEnd commands respectively. The parameters in the ArcStart template must be equal to the values of the corresponding welding variables on the actual controller.

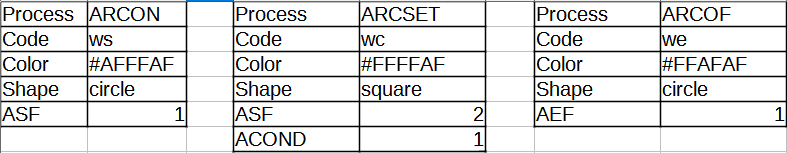

The templates motoman_ws.csv, motoman_wc.csv and motoman_we.csv are used as Motoman welding templates for weld start (ARCON), weld continue (ARCSET) and weld end (ARCOF) commands respectively. The parameters 'ASF', 'ACOND' and 'AEF' in these templates must be equal to the values of the corresponding welding variables on the real controller.