This section describes how to automatically calibrate your robot using RoboDK TwinTrack and your measurement system. Robot calibration allows you to improve robot accuracy to up to 0.150 mm when you generate programs offline or using TwinTrack teach by demonstration tools in RoboDK (the level of accuracy highly depends on the quality and size of the robot).

It is recommended to perform the robot calibration after you build your robot cell or you make major modifications (such as changing the payload of your tool). This helps obtaining the best accuracy.

Before you begin the calibration, you can model your cell in RoboDK to automatically avoid collisions. You can use basic geometries such as planes or cubes to avoid unwanted areas. You can also limit the joint space of the robot.

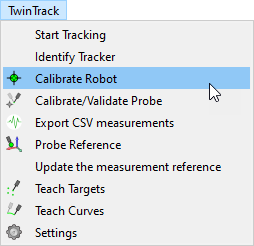

You can select TwinTrack➔Calibrate robot to start the robot calibration procedure.

This operation will guide you to calibrate the robot, including the automatic generation of points for calibration and validation. RoboDK can automatically generate points that are visible by the tracker.

The robot calibration procedure requires taking around 200 measurements. The procedure starts by taking some measurements around the home position of the robot.

Once the setup is ready and the communication with the robot are properly stablished, the calibration procedure should take 15-30 minutes.

The system requires no special fixtures or accessories, it simply tracks the position of the tool with respect to the tracker reference.

It’s fine if you miss some measurements because the targets are not visible.